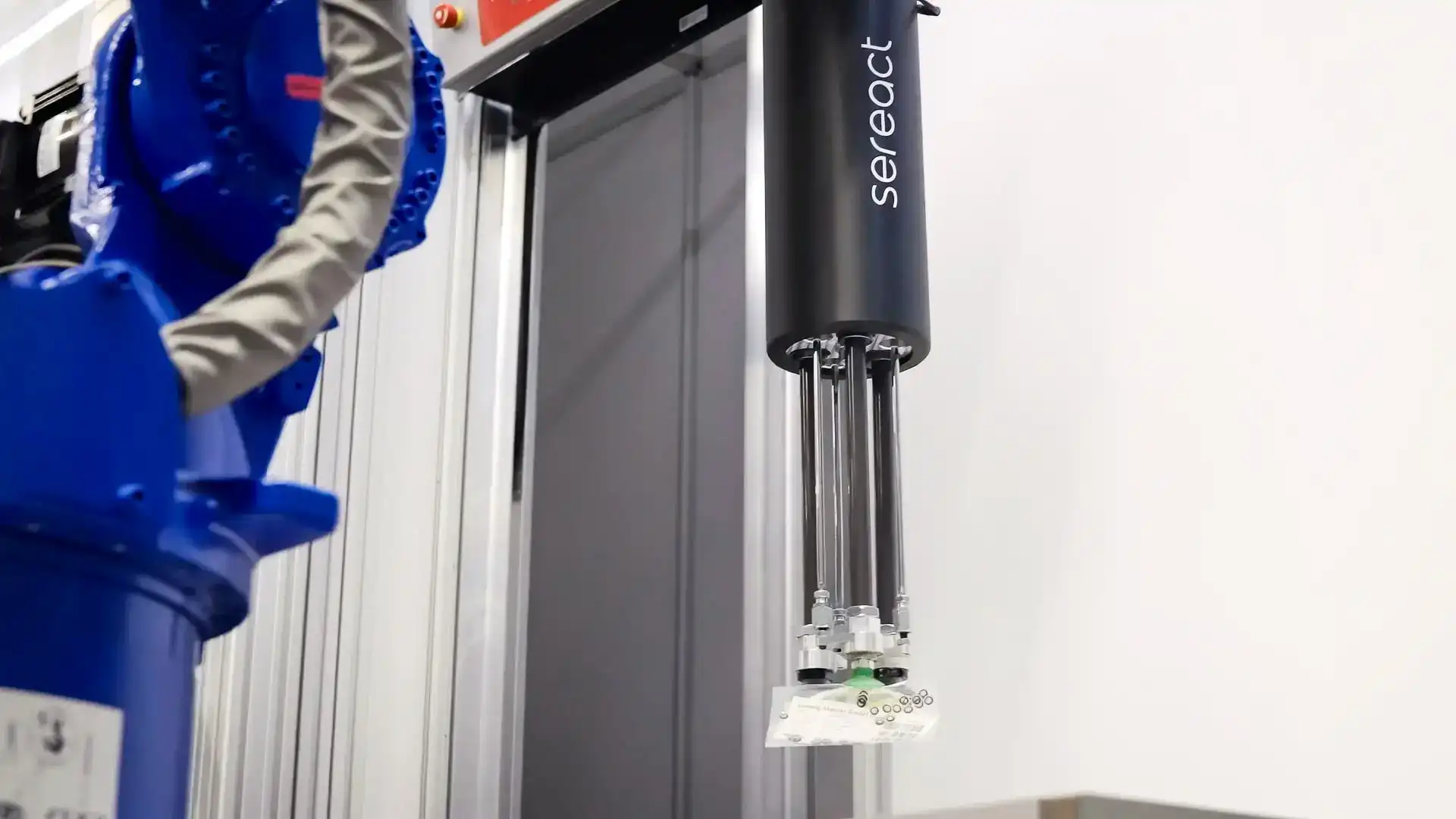

Sereact delivers instant warehouse intelligence. Built on the world's largest dataset of real picks, 98%+ accuracy on any robot with zero retraining & retooling.

"Built for Warehouses. Proven in Warehouses."

The reality every warehouse faces

Labour is scarce. Costs are rising.

Legacy automation is falling behind.

Labor is harder to secure than ever

During peak periods, the workforce simply isn’t there. Attracting and retaining staff is a continuous struggle.

Operational costs continue to rise

Rising wages, training, energy, and downtime steadily erode margins, while systems that demand constant adjustments only increase costs.

Automation that works in demos fails in reality

Robots look good in controlled labs, but messy warehouses expose their limits.

Most solutions still rely on human intervention

Instead of reducing headcount, they keep humans tied up with supervision and intervention.

Built to fit every workflow.

Sereact integrates seamlessly with the systems warehouses already rely on. From cube storage to conveyors, our AI brain powers robots to pick, place, and adapt across every stage of the operation.

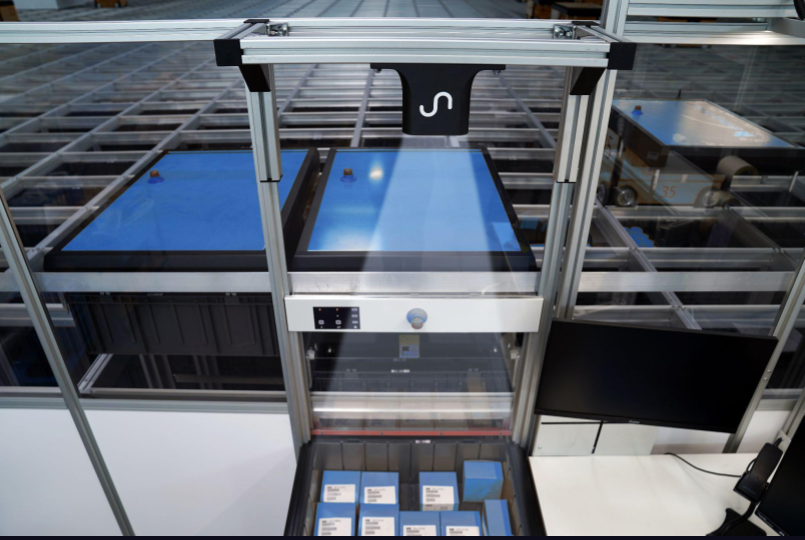

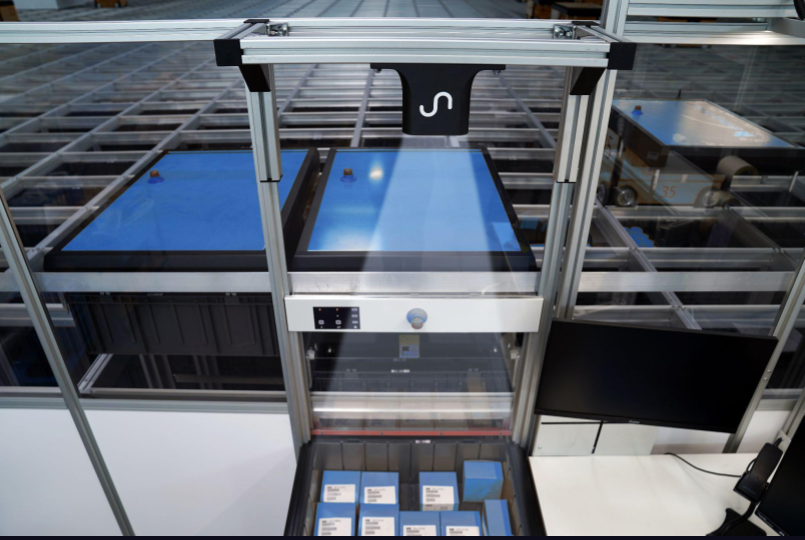

Lens

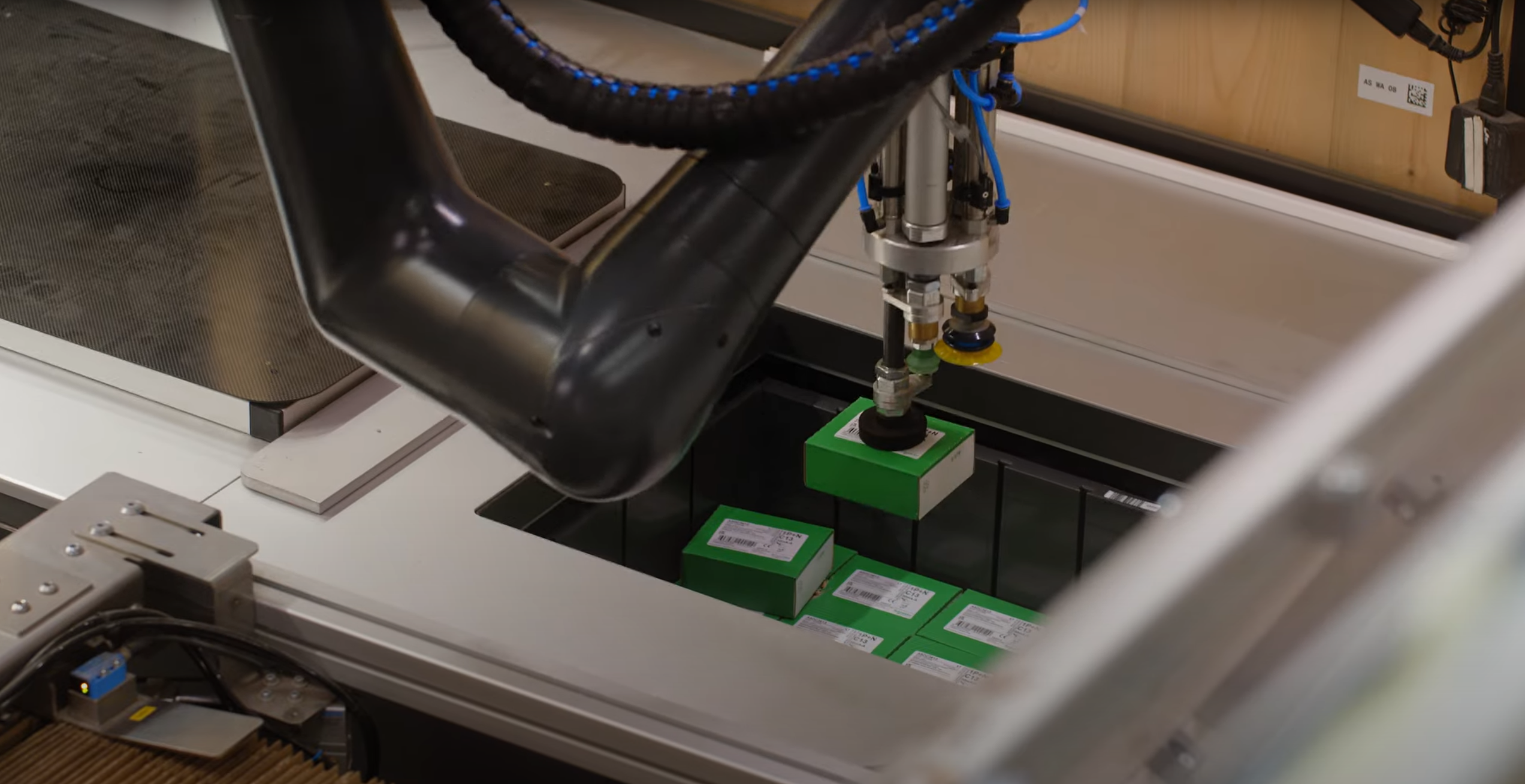

Direct integration at AutoStore ports and other automated storage systems. Pick and place instantly with no retraining, no matter the item variety.

Putwall

Automated sortation for batch-picking and returns. Robots slot items with speed, precision, and consistency.

Goods-to-Robot-Picking

Place items directly onto conveyors for packing, sortation, or shipping. Continuous flow with no manual intervention.

AMR Induct

Load and unload autonomous mobile robots without human assistance. Hardware-agnostic and plug-and-play with any fleet.

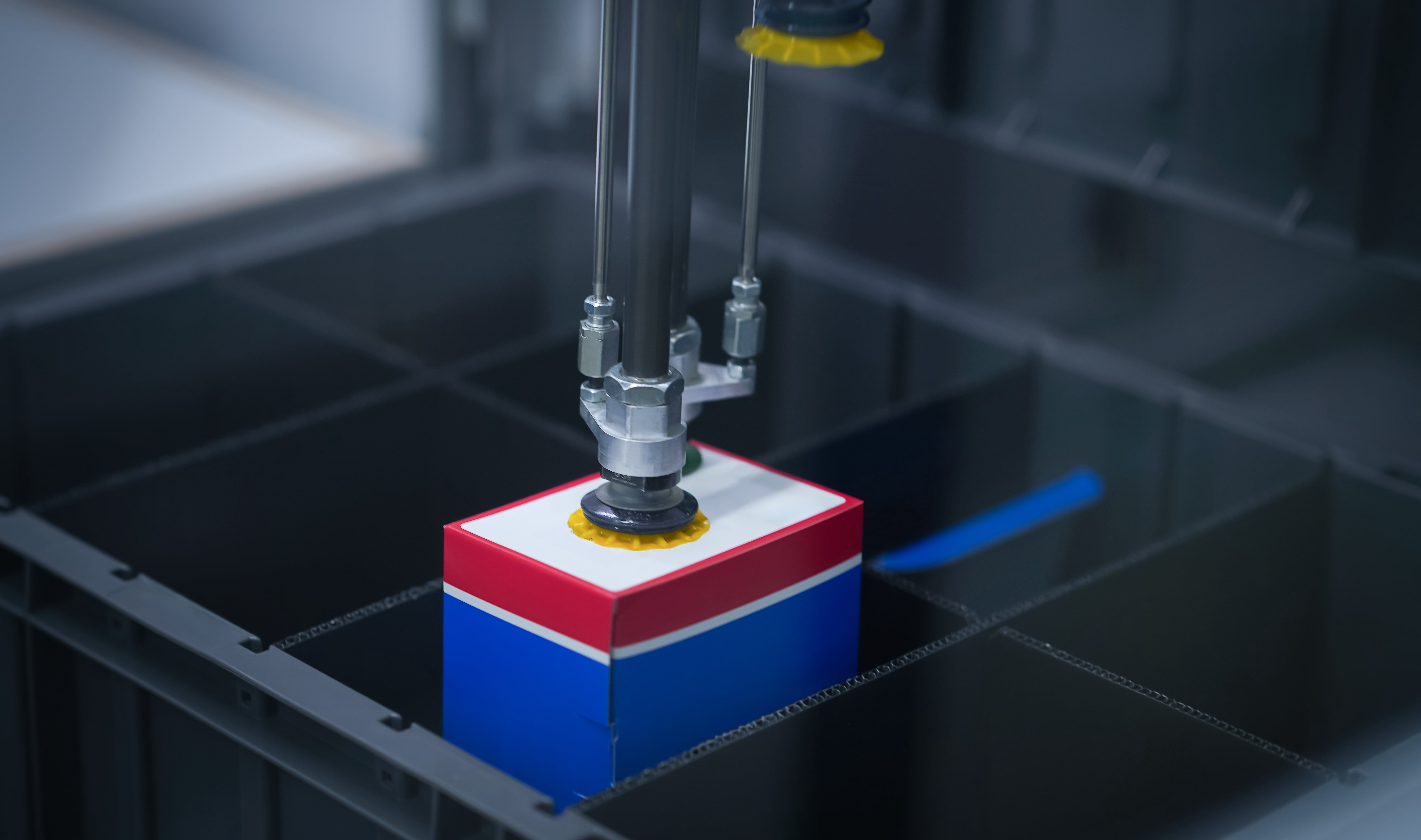

Bin Densification

Maximise storage with high-density layouts. Our AI handles tight, complex environments where others fail.

Lens

Direct integration at AutoStore ports and other automated storage systems. Pick and place instantly with no retraining, no matter the item variety.

Putwall

Automated sortation for batch-picking and returns. Robots slot items with speed, precision, and consistency.

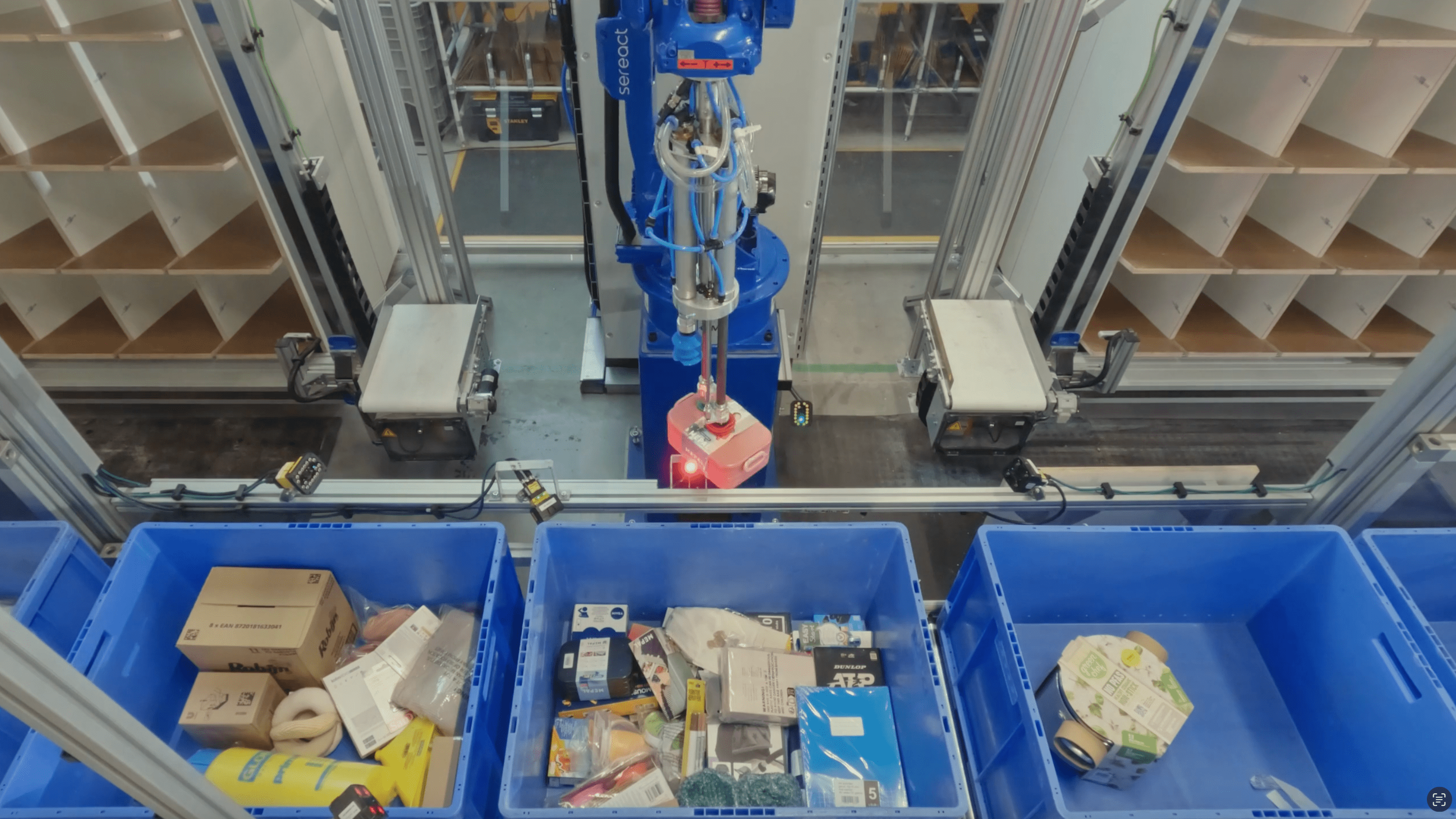

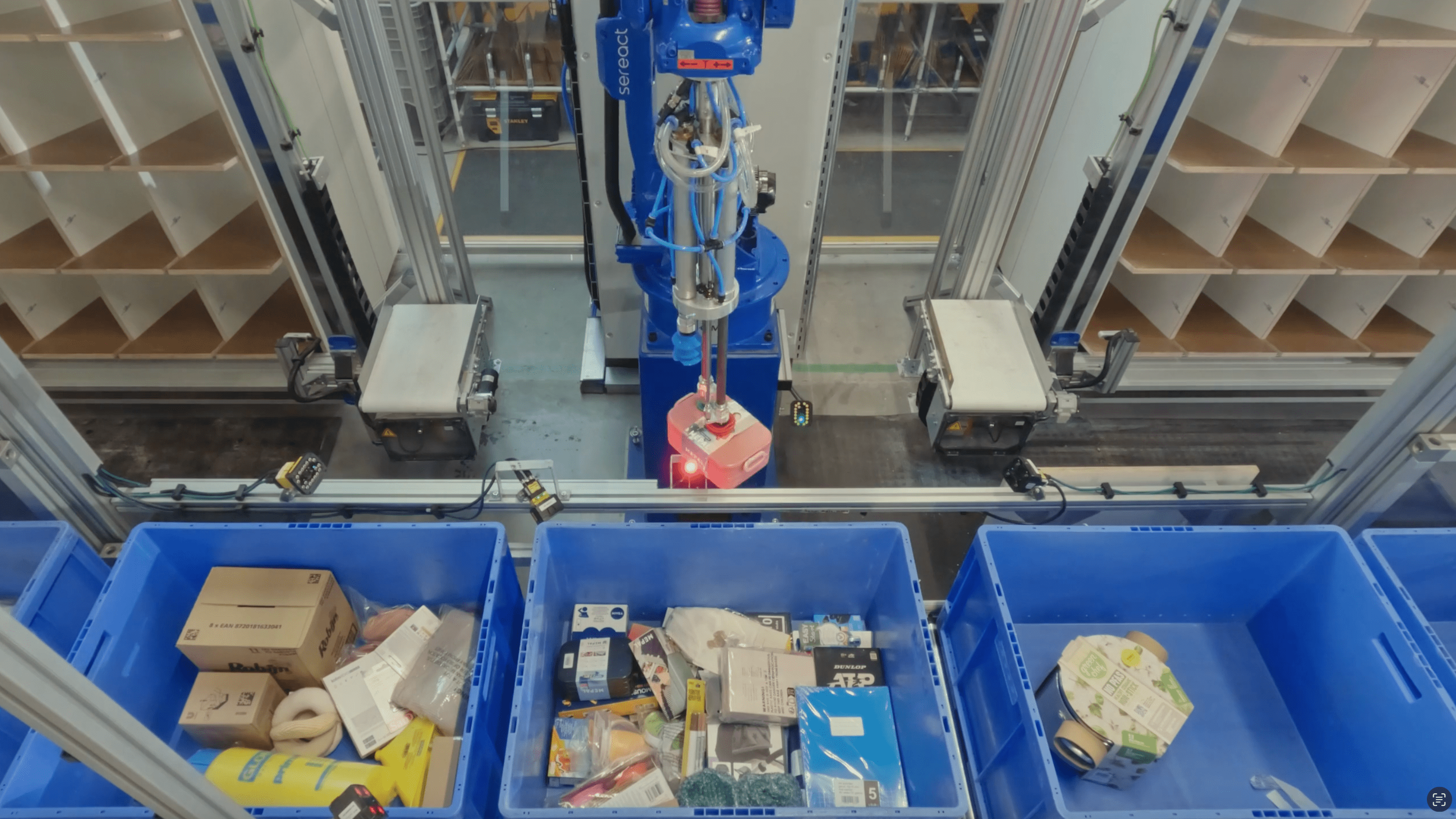

Goods-to-Robot-Picking

Place items directly onto conveyors for packing, sortation, or shipping. Continuous flow with no manual intervention.

AMR Induct

Load and unload autonomous mobile robots without human assistance. Hardware-agnostic and plug-and-play with any fleet.

Bin Densification

Maximise storage with high-density layouts. Our AI handles tight, complex environments where others fail.

Sereact is built for the real world.

Live in production. Real-time adaptive.

Autonomous by design.

"What impressed us most is that it can handle our full range of more than 500,000 SKUs without cherry-picking. And working with the Sereact team has been excellent, they respond immediately and actively think with us about every step of the integration."

"With Sereact, we have found a solution that fully integrates both two-finger and suction grippers, enabling perfect gripper/product matching without the need for time-consuming object teach-in. Sereact's advanced technology is able to handle objects accurately and operate completely autonomously without human intervention."

"After evaluating five suppliers for our picking robot project, Sereact stood out as the clear choice and a market leader in AI-based solutions. Their cutting-edge technology, combined with a deep understanding of our logistics requirements, made them the ideal partner."

Not robots. Results.

Reduce Expenses

Labour costs keep climbing, especially with overhead.

Cut up to 77% of costs with AI-powered picking. No retraining, no retooling. ROI in weeks.

Overcome Labour Shortages

Hiring is harder than ever, and peaks crush your capacity.

Sereact runs 24/7 with no supervision, scaling throughput without extra headcount.

Increase Productivity

Other robots need retraining and constant tuning.

Sereact installs in a day, works autonomously, and delivers 98%+ accuracy from the first pick.

Visual Intelligence for data-driven Warehousing

Sereact doesn't just automate tasks, it gives robots the intelligence to handle reality. From day one, fully autonomous. No retraining. No supervision.

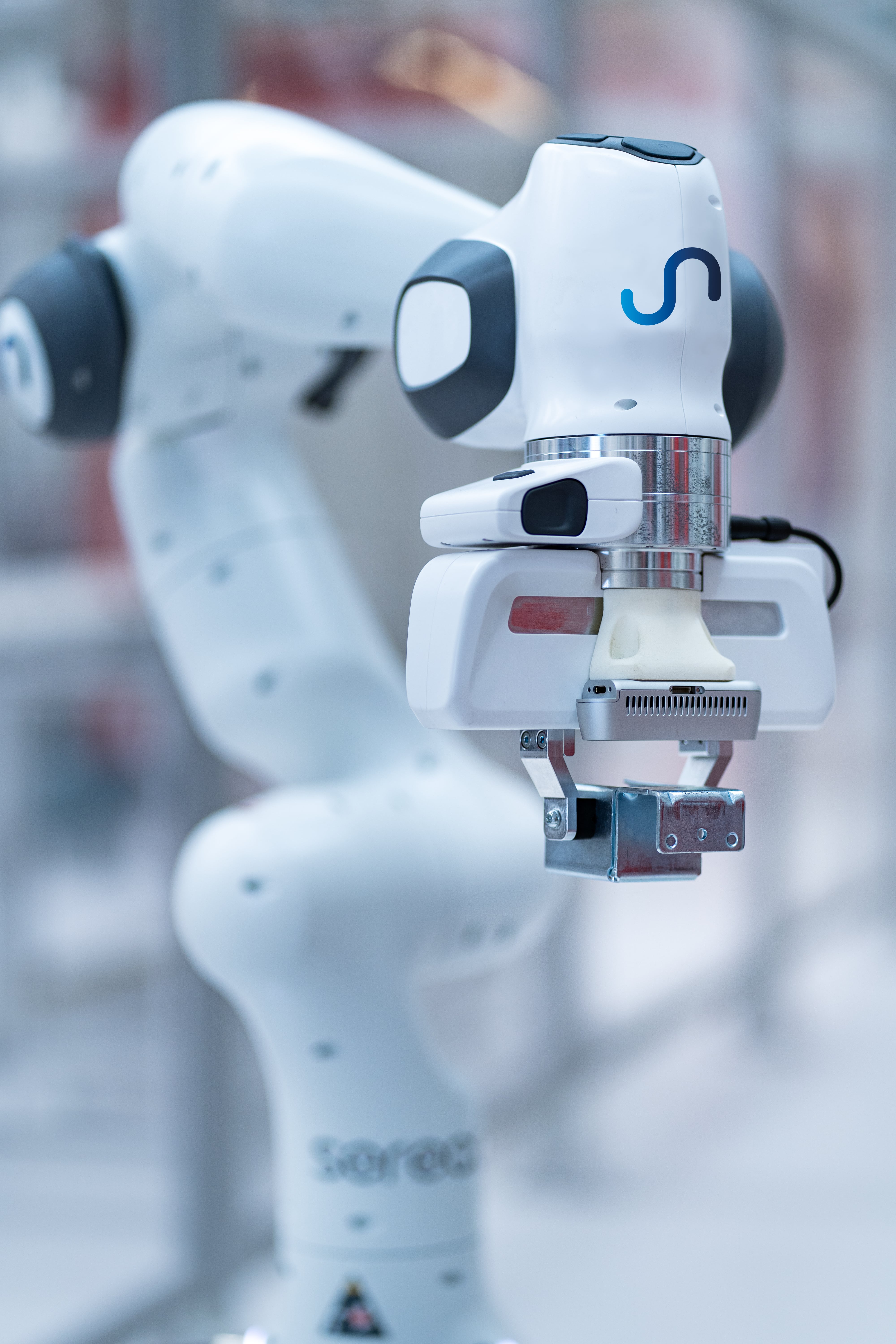

Most robotics AI only works in controlled lab conditions. Sereact's Vision Language Action Model (VLAM) is trained on millions of real-world picks, making it the first production-ready AI brain for robots.

The real AI revolution is on the warehouse floor.

Sereact is the first production-ready Vision Language Action Model (VLAM), an AI brain for every robot, built to handle reality.

Raas

Robot-as-a-Service.

Subscription pricing. ROI in weeks.

98%+

Accuracy from day one.

Runs on your existing robots.

Case Studies & Testimonials

"With Sereact we expanded our product range by thousands of items while keeping operations running smoothly. The robot simply works side by side with our team, like it’s always been here."

Marvin Kneuer, Sonepar Swiss

"Our employees are proud to work alongside the robots. With Sereact, we’re taking real steps toward a zero-touch fulfillment strategy."

Martin Anderegg, OPO Oeschger

"With Sereact we launched our first picking arm in just three months and it’s improving every day through self-learning AI."

Luca Graf, MS Direct AG

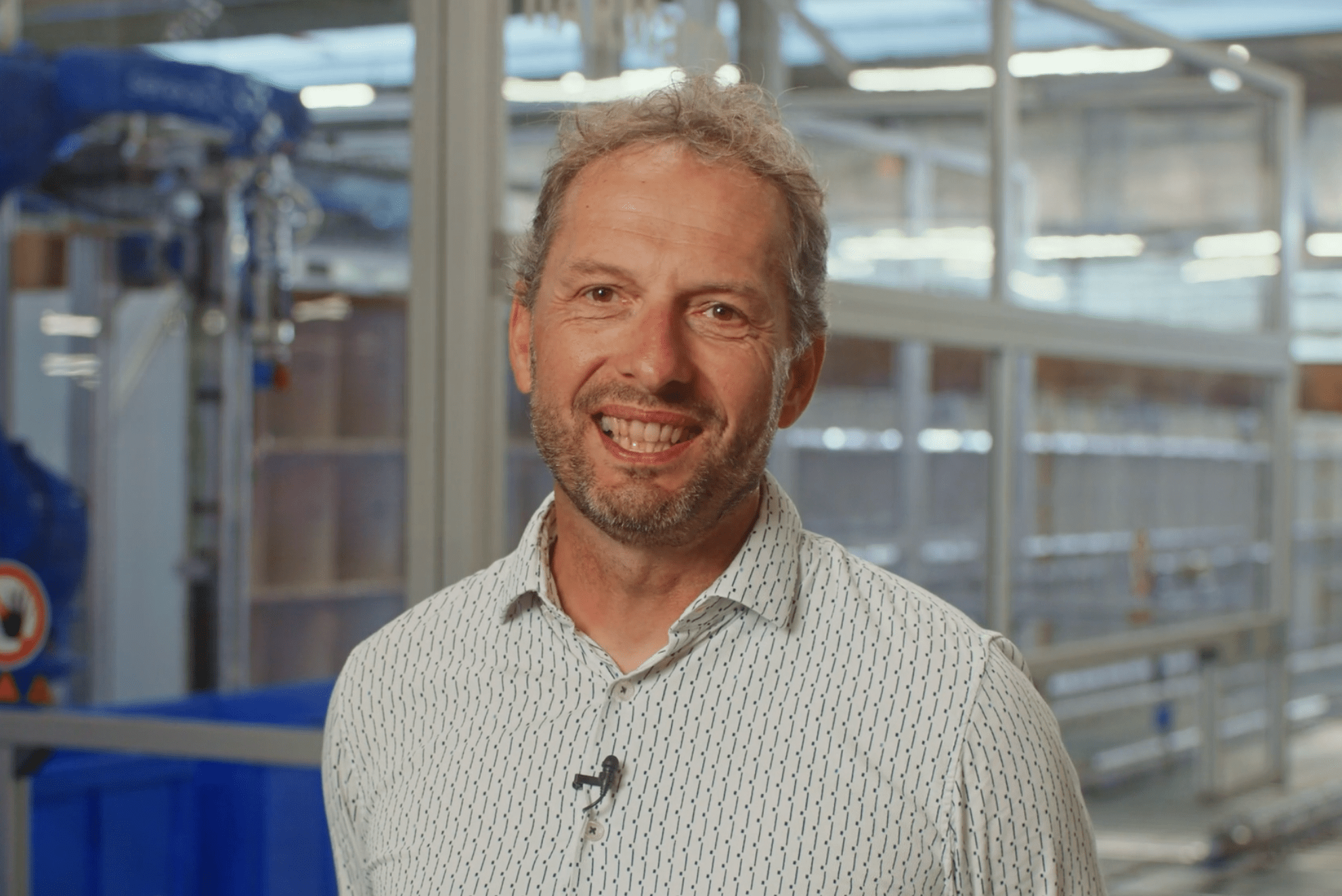

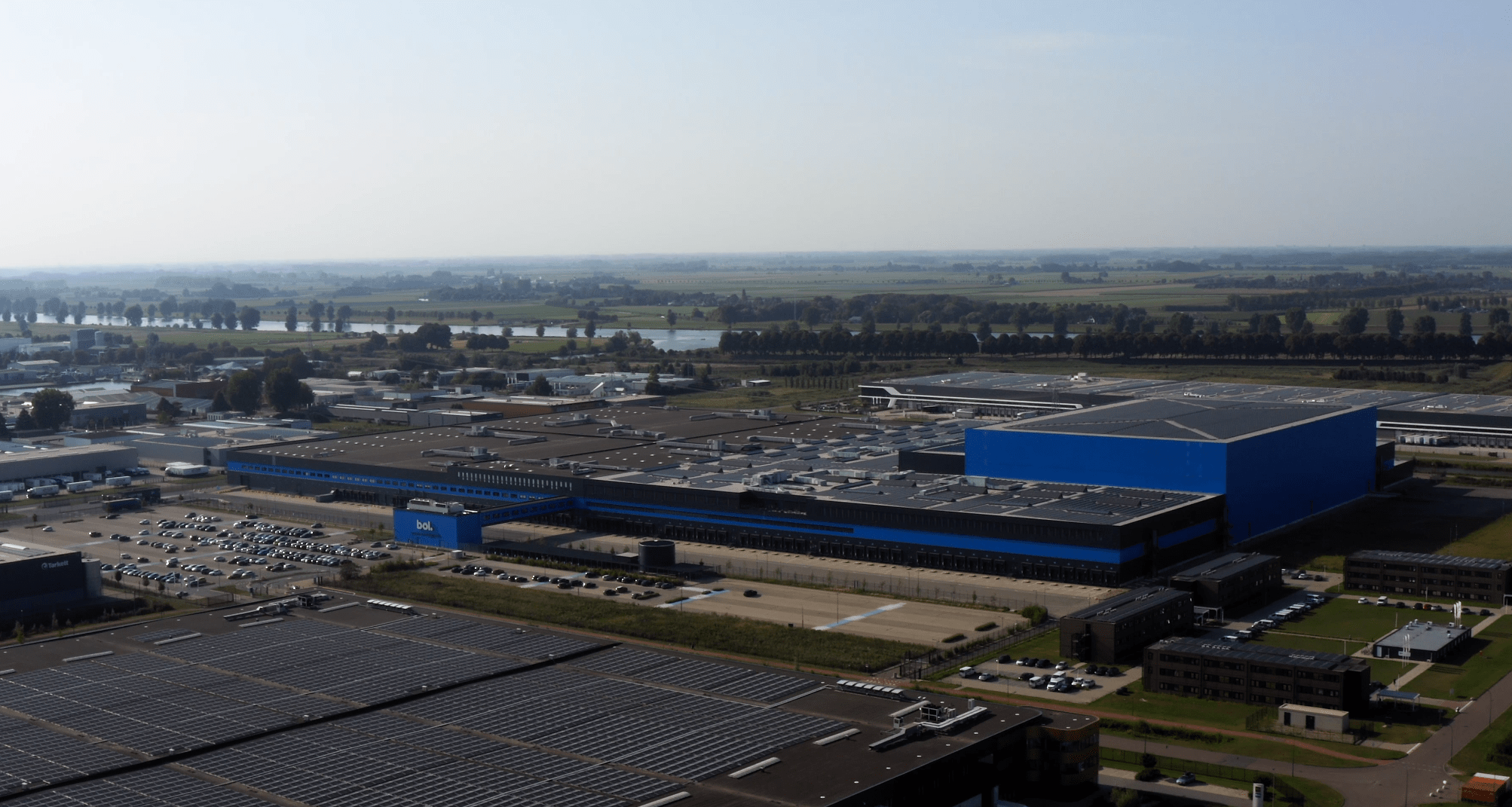

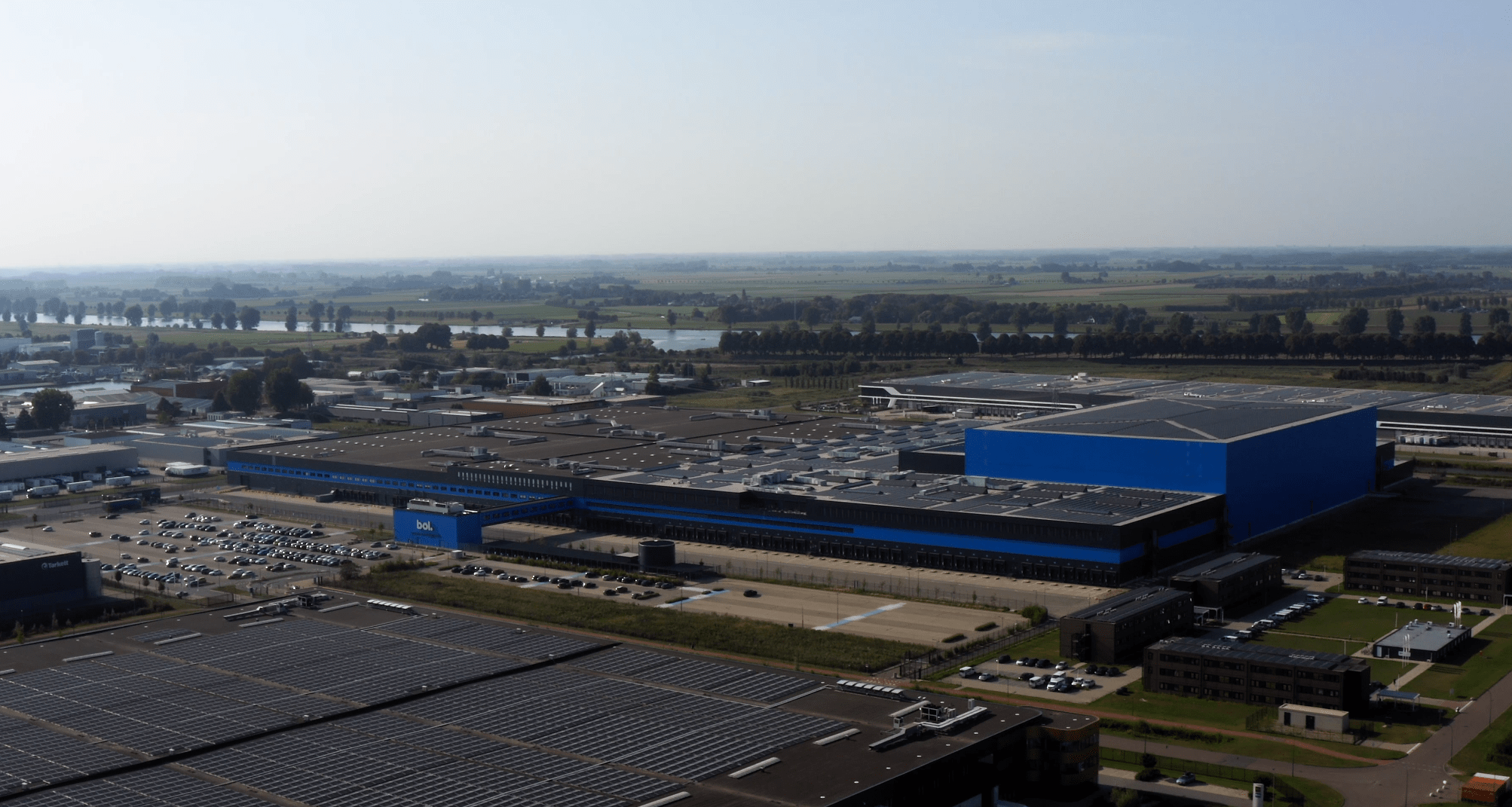

"We want to test with the robots in our real production area. That's why we put this robot here on our most difficult area with the most integrations and the most difficult handlings. We're learning about the KPIs and what's possible with the robot because for future business cases it's important that you have the right numbers."

Hugo Driesse, Logistic Process Engineer at BOL

"With Sereact we expanded our product range by thousands of items while keeping operations running smoothly. The robot simply works side by side with our team, like it’s always been here."

Marvin Kneuer, Sonepar Swiss

"Our employees are proud to work alongside the robots. With Sereact, we’re taking real steps toward a zero-touch fulfillment strategy."

Martin Anderegg, OPO Oeschger

"With Sereact we launched our first picking arm in just three months and it’s improving every day through self-learning AI."

Luca Graf, MS Direct AG

"We want to test with the robots in our real production area. That's why we put this robot here on our most difficult area with the most integrations and the most difficult handlings. We're learning about the KPIs and what's possible with the robot because for future business cases it's important that you have the right numbers."

Hugo Driesse, Logistic Process Engineer at BOL

News

Be ready before peak season.

Go live in weeks with Sereact - automation ready when you need it most.

In 30 minutes, we'll show you how Sereact installs in a day and starts delivering ROI from the first pick.